Suppose you are visiting a supercomputing centre for several days. Each day you submit your compute jobs and then go to a nearby tropical garden. While your jobs are being computed, you enjoy fresh tropical fruit, listen to exotic birds and read a recent issue of your favourite scientific journal.

Layard’s Parakeet, photo by Hafiz Issadeen. Source: Wikimedia Commons

Sounds too good to be true? But this could be our near future. In fact, modern supercomputers consume so much energy (and dissipate so much heat), that we must reuse that heat if we want to be green and be kind to Mother Nature.

Recent advances in power-related high-performance computing technologies are two-fold: (1) minimize the use of energy to run a computer, and (2) minimize “useless” energy spending (that does not directly contribute to calculations), such as energy used to run a cooling system.

Attempts to decrease power consumption are a real headache for system designers. If you take a look at the most powerful systems in the latest June 2012 TOP500 list (Excel version recommended), you’ll see that many top machines (in the petaflops range) require on the order of one or two megawatts of power. A typical nuclear power plant produces a thousand times more energy, which led to an (ironic) saying that we can build exaflops machines even today, but we would need a nuclear power plant to provide them with electricity.

Power usage of auxiliary equipment, such as lighting and cooling systems, was a concern until recently. In worst-case scenarios, auxiliary equipment could consume as much power as the computing equipment itself. However, lately this problem was addressed, and now it is mostly solved: the best of breed data centres have achieved the power usage effectiveness (PUE) of 1,15..1,25, which means that mere 15% to 25% of energy used to run servers are required to run auxiliary equipment. For example, Google boasts a PUE of 1,13, or even 1,06 — depending on how you measure it.

So, the power consumption of the top machines is impressive, and there are no indications that future computers will consume less power. Most likely, they will draw the same amount of power (one or two MWatts, which is manageable), but will simply perform more calculations within that power budget.

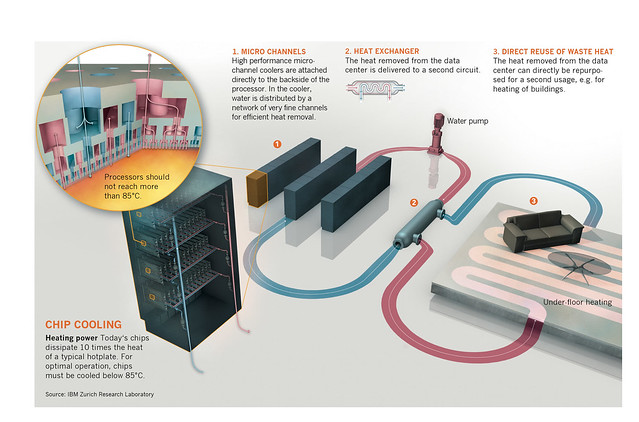

The worst thing about the current power consumption by supercomputers (and big data centres in general) is not that they draw lots of power — it is that they don’t reuse the dissipated heat. Indeed, even the latest and greatest big data centres and HPC installations that boast of using most advanced cooling technologies still don’t reuse heat — they mostly dissipate it into the atmosphere, in one way or another. Systems such as Aquasar (see image below) are still a whim rather that the norm (see, however, the list of those whims implemented to date).

IBM Aquasar cooling system. Copyright: IBM. Source: Flickr

What is so bad about just dissipating heat? First, it means that heat is wasted — it’s lost forever. Second, what if heat dissipation has the potential to create a local climate change in the vicinity of a supercomputer centre? SuperMUC, currently the fastest computer in Europe, draws 3,4 MWatts of power. In 24 hours, its power consumption is roughly 80 MWh. The daily per capita electric energy consumption in Germany is about 20 kWh (that includes household, industrial and all other usage), therefore SuperMUC draws as much power as would a town with a population of 4,000. (For comparison, the population of Garching bei München, where SuperMUC is located, is roughly 16,000).

But there are better ways to handle the heat rather than to dissipate it, and here is how. SuperMUC uses liquid cooling — that is, warm water passes through heat sinks in the compute nodes, getting hotter in the process — up to 40°C. This hot water can be used in a building heating process called concrete core temperature control. (Details presented by Dr. Matthias Brehm of LRZ at ISC’12 in Hamburg)

“With the reinforcement and tube mats already installed, concrete is being laid at the Post Tower in Bonn, Germany”. Image © Heinle, Wischer und Partner, Köln. Source: EnOB

In short, water pipes are installed inside concrete slabs during the building construction. After construction is complete, pumping hot water through those pipes causes heating of the indoor space. That’s how heat from supercomputers can be reused. However, this scheme is not very useful in summer, because in summer you need to take away extra heat from the rooms by pumping cold water through the pipes. Therefore, in summer you are left stuck with the hot water produced by your supercomputer.

Is there a way to reuse the heat all the year round? Yes, there is. The answer is greenhouse heat exchange. We can pump hot water through pipes laid out in a greenhouse, thereby heating air and fostering growth of plants.

Excellent examples of waste heat reuse for agricultural purposes are Tropenhaus Wolhusen and Tropenhaus Frutigen, both in Switzerland. They both produce tropical fruit as well as fish, specializing in tilapia and sturgeon, respectively. At Tropenhaus Wolhusen, the greenhouse for fruit production occupies 5,300 m², with an additional tropical garden for visitors taking up 2,100 m².

As for the costs of greenhouse construction, they differ depending on location and materials used. In the USA, Department of Agriculture provides citizens with a wealth of advice. Dr. J. Raymond Kessler, Jr. of Auburn University, Alabama, compiled an excellent guide, “Starting a Greenhouse Business”. If you take a look at Table 1, erecting greenhouse outer structures and covering them with double layer 6 mm plastic walls costs $43,565 for 11,520 square feet of area (as of 2006). Converting this to European units would yield €33,183 for 1037 m² — or €32 per m². Capital expenses other than this primary construction work are also very well detailed. (If you have read to this point and are seriously thinking of starting your own greenhouse business, consult the literature referenced in the end of Dr. Kessler’s guide. He also recommended an industry magazine, “Greenhouse Grower”, for those who are really into it).

While Switzerland chose to produce tropical fruit, in other parts of the world waste heat is used to grow more conventional produce, such as tomatoes in Canada. Dr. Joshua M. Pearce and his co-researcher Rob Andrews from Queen’s University made careful calculations regarding the use of warm water from industrial processes to grow tomatoes in large-scale greenhouses.

Dr. Joshua M. Pearce and Rob Andrews investigated profitability of using industrial waste heat for growing tomatoes in Canadian climate. Image source: Queen’s University, Canada.

Their calculations indicate (click for a direct link to PDF version of their article) that reusing 5,1 MWatts of heat allows to maintain acceptable temperatures, even in the moderate climate of Ontario, in a greenhouse as large as 15,800 m² — which yields tomato crops of 735 tonnes each year, with a revenue of more than $1M!

If a greenhouse is built near SuperMUC, then, in analogous conditions, it would give 1,340 kilograms of tomatoes every single day. This is more than enough to load a light truck such as one below. Need we say more?

Volkswagen Transporter Dropside. Image source: “Car And Van Deals Direct”

That’s a good article and I love the idea. Unfortunately here in Hong Kong it’s already too hot most time of the year, so we won’t be able to grow our own tomatoes anytime soon with data center heat.

I read of a small project reusing the heat for a restaurant kitchen, but that is far from the magnitude of reusing a complete supercomputer or datacenter’s heat – and it comes with lots of implications (many small size kitchens).

In fact, I am looking at a system dissipating around 70kW outside my window right now, and there really is no way to do anything useful and practical with it (outside air temp around 25.8° and it’s still the cold season now). A few weeks ago, we could still use it to heat our office though.

Alex